Introduction

An essential task of analysis using energy dispersive

x-ray spectroscopy (EDS) is to determine the elemental composition of a sample quantitatively. In recognition of the importance of this task, great care is taken to develop robust analytical models to accurately and precisely determine a sample’s composition. In this application note, we report a summary of the evaluation of the quantitative performance of EDS standardless analysis in the EDAX APEX™ 3.0 EDS Standard and Advanced software programs.

Results and Discussion

An EDS spectrum is analyzed during quantitative analysis to determine the weight or atomic fraction of elements present in a sample. We have published several articles that explain the detailed process of this1, 2, 3, but in summary, for standardless analysis, the x-rays characteristic of elements present in the sample are separated from each other and the Bremsstrahlung background. Then, an iterative algorithm is applied to correct for excitation efficiency (also a function of the primary electron energy), self-absorption of x-rays that are generated in the sample, possible enhancements of an x-ray line’s intensity by secondary x-ray fluorescence, and detector efficiencies to convert from net x-ray intensities to elemental composition. The model used in the iterative algorithm (normalized standardless eZAF corrected analysis) has been developed continuously as there is a greater understanding of the physical processes of x-ray generation, emission, and detection4.

Before release of a new APEX software version, the analytical performance of APEX EDS Standard and Advanced are validated by evaluation of spectra collected from more than sixty certified standards, including minerals, metal alloys, and binary compounds. We determine the total absolute error by summing the absolute difference between the measured and known composition for each element, i, present in the sample:

Equation 1.

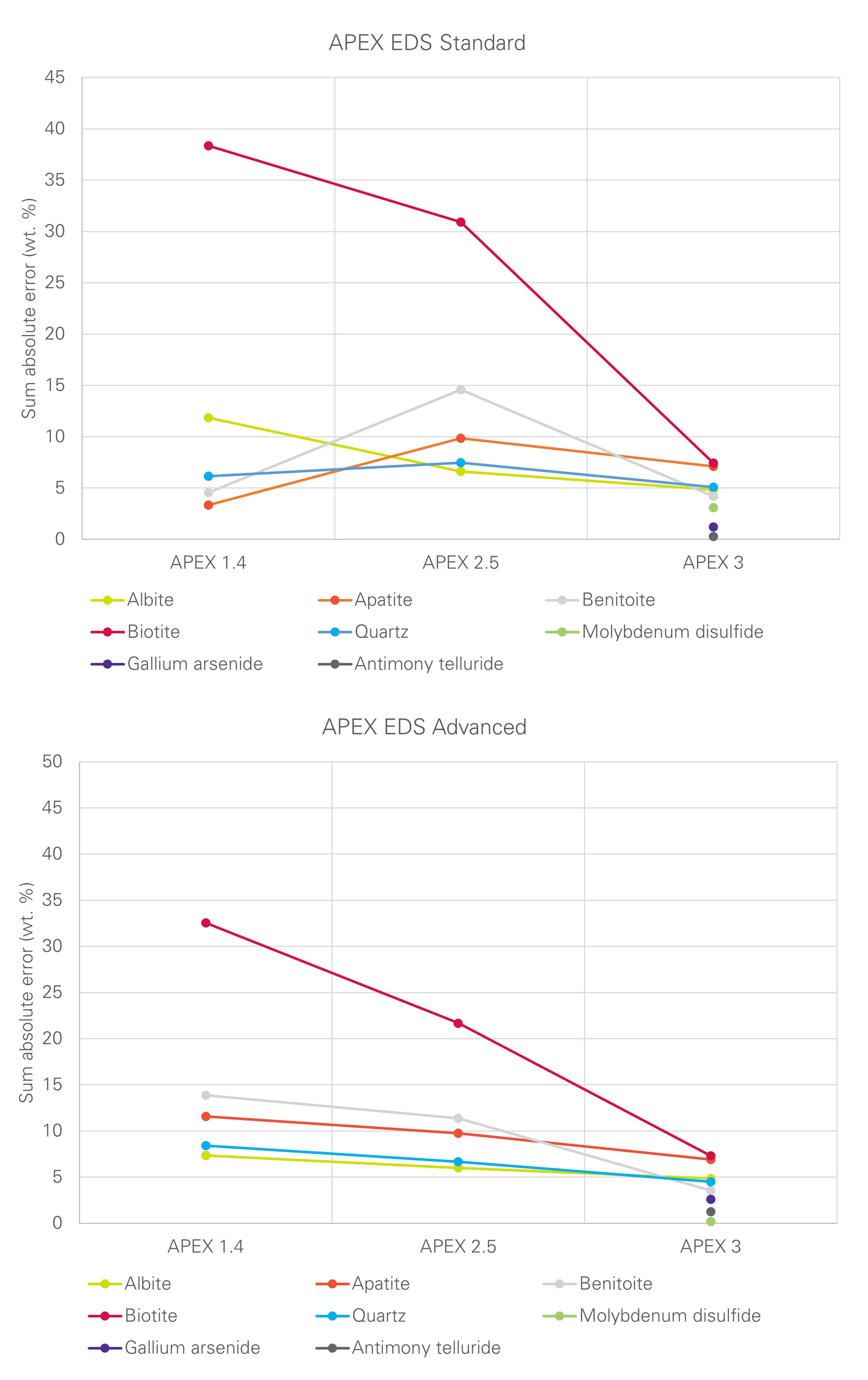

Figure 1 reveals the significant improvements in the accuracy of compositional analysis by standardless eZAF correction in APEX software versions, emphasizing the step change in accuracy available with APEX EDS software version 3.0. Furthermore, APEX EDS Advanced software offers improved accuracy through the use of a computed physical model of Bremsstrahlung background rather than the mathematical filtering approach (SNIP) used in APEX EDS Standard software and other analysis software that

is available commercially. Figure 2 shows the improvement for a selection of standards that were analyzed.

Figure 1. Improvement of the accuracy of compositional analysis of APEX EDS software evaluated by analysis of mineral, metal, and compound standards.

APEX EDS Standard software and other analysis software that is available commercially. Figure 2 shows the improvement for a selection of standards that were analyzed.

Figure 2. Error in the analysis of selected standards.

Conclusion

As seen from the figures, standardless analysis using eZAF correction has improved dramatically in recent years in APEX EDS Software. However, only you can determine if this level of accuracy is sufficient for the analysis challenges you face. If not, APEX EDS Advanced software offers the possibility of further improvements using standards customized coefficients (SCC) for eZAF standardless analysis—an empirical database that optimizes the iterative model for your installation—or full standards quantification (FSQ).

References

- Ways to improve the EDS quantitative results accuracy: Efficiency and eZAF SCC database. EDAX Insight Vol. 19, Issue 3. September 2021.

- Ways to improve the EDS quantitative results accuracy: eZAF MACC database and correction avoidance. EDAX Insight Vol. 19, Issue 4. December 2021.

- Ways to improve EDS quantitative results accuracy: FSQ and SmartStandards. EDAX Insight Vol. 19, Issue 4. December 2021.

- F. Eggert. Abilities towards improved accuracy in EPMA. Microscopy and Microanalysis (M&M) 2021.