Benefits

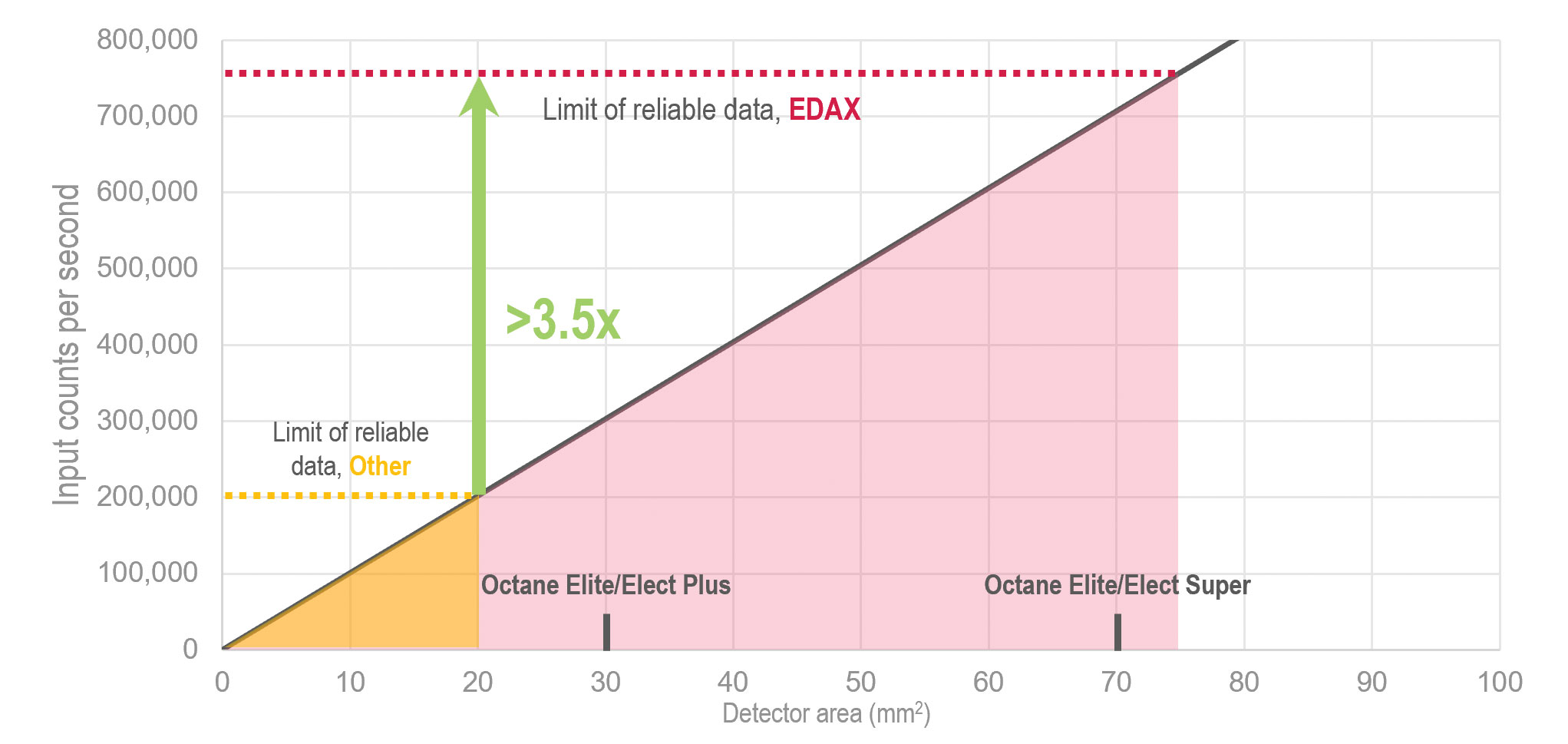

- Provides accurate compositional and crystallographic data collection >3.5x faster than other systems

- Expands your analytical capabilities to include the widest range of materials, including complex samples

- Delivers results in minutes rather than hours or days

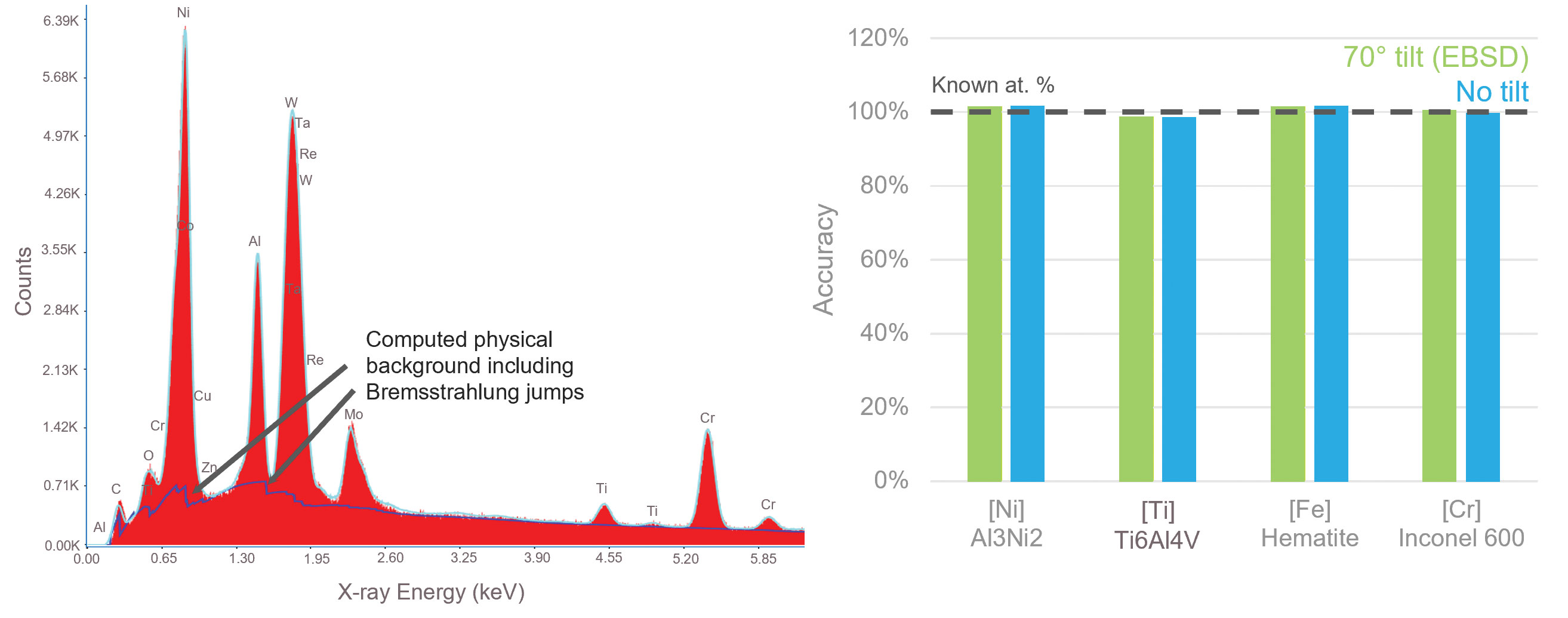

- Produces superior compositional analysis at EBSD geometries

- Optimizes analysis with a single EDS – EBSD interface using APEX™ software

As a standalone technique, EBSD is incredibly adept at discerning between different phases based on their crystallographic disparities. However, when you combine the chemical insights from EDS with the crystallographic data from EBSD, it delivers a highly potent analytical approach that allows users to separate phases with similar crystallography and eliminate ambiguity and error in multi-phase samples.

Figure 1. Pegasus delivers dependable answers with one scan of the electron beam. The graph shows EDS input counts by detector area at conditions suitable for high-speed EBSD analysis using the Velocity EBSD detectors on a copper sample with 20 kV accelerating voltage and 20 nA beam current.

In order to achieve this groundbreaking synergy, Pegasus utilizes the EDAX Velocity™ and Clarity™ EBSD systems to gather crystallographic information. Depending on your research requirements, the Velocity cameras provide high-speed collection on a wide array of sample types, while the Clarity direct detectors are ideal for beam-sensitive samples and deliver unparalleled performance down to 3 kV.

Furthermore, Pegasus leverages the efficiency of the EDAX Octane Elect and Octane Elite EDS detectors to collect superior results 3.5 times faster than other systems and at EBSD geometries. With the Octane Elite Ultra, you can extend sensitivity to light and heavy elements at accelerating voltages up to 30 kV. This eliminates the need for a secondary EDS detector, meeting your demanding application needs as a standalone or dual EBSD-EDS technique.

The intuitive APEX software connects powerful analytical EDS – EBSD routines to collect and report high-quality data quickly, easily, and reliably. This combination with EDAX hardware increases user productivity and offers the best solution for simultaneous EDS – EBSD microstructural characterization.

Figure 2. Pegasus produces supreme compositional analysis at EBSD geometries, correcting for absorption effects due to tilt and yielding EDS results comparable to conventional analysis at typical EBSD conditions. The chart to the right shows that at the typical 70° sample tilt used for EBSD analysis, the at% accuracy is at or near 100%. The data above was recorded with 20 kV accelerating voltage, 2.5 nA beam current, and 100k cps EDS count rate.

Resources

Product bulletins/Datasheets