Introduction

When a new x-ray energy dispersive spectroscopy (EDS) system for the scanning electron microscope (SEM) is introduced, many microscopists and microanalysts ask the same few questions—"What size is it?”, “What is the energy resolution [at Mn Kα]?”, and “Does it have a window?”. Based on the answers to these three questions alone, many believe that they understand what a new model of EDS detector can offer them.

Is it the case that an EDS detector can be understood in just these questions? The EDAX® Octane Elite Ultra EDS system for SEMs and dual beam instruments was recently introduced. The answers to those three ubiquitous questions are: 160 mm2 (size), 128 eV (resolution), and windowless. Before reading on further, take a moment to consider what you think this detector might be good for and, importantly, any limitations you think it may have.

Figure 1. EDAX Octane Elite Ultra EDS system.

Discussion

For an experienced microscopist, it is immediately clear that rapid elemental mapping should be possible due to a very large active area and good energy resolution. That is true, elemental maps can be collected with up to 20x larger area coverage or the time to collect a map is reduced by ~95% (at the same signal-to-noise ratio) than basic EDS systems, see EDAX Insight Vol. 22 No. 4 for more information. Due to the efficient collection of x-rays by a large area detector, the system is also assumed—correctly in this case—to be suitable for operation of the SEM at low beam current and accelerating voltages, offering improved spatial resolution, and avoiding damage to fragile samples by the electron beam. Furthermore, an aptness to detect and analyze light elements is presumed due to the avoidance of absorbance of low energy x-rays from a window material, see EDAX Insight Vol. 22 No. 4 for an example of improved mapping of boron.

Windowless detectors are not new to electron microscopy; they have been used extensively in transmission electron microscope (TEM) applications due to their superior detection efficiencies. However, they have gained limited adoption in SEM applications as the list of negative preconceptions is often longer than the perceived benefits. Common concerns that are voiced include:

- Provides qualitative information only and cannot be used for quantitative microanalysis

- Limited to evaluation of light elements due to the need to use at low (<10 kV) accelerating voltages

- Require a ‘buddy detector’ for routine tasks (adding significant cost)

- Detectors are easily damaged by operator error or contamination and therefore limited to installation on select microscope models where extensive interlocking schemes have been devised

In the previous EDAX Insight release, we showed that the negative preconceptions were not true for all windowless EDS detectors for SEMs, and demonstrated that the Octane Elite Ultra EDS system can be used for quantitative analysis of a wide range of materials, including high atomic number elements at accelerating voltages of up to 30 kV.

When investing in new instruments, the ability to deliver outstanding results is not the only concern. The system must be reliable and deliver value for money over the long term. The major concern to reliability of windowless detectors is that they are not resistant to damage by accidental operator error or malfunction of the SEM. In particular, exposure to atmospheric conditions during routine operation of the SEM, e.g., venting the chamber to exchange samples. Exposure to air when the sensor is cold causes water to condense on the (cold) sensor surface causing catastrophic failure of the detector module and a very expensive repair. Therefore, windowless EDS detectors in the SEM have been limited in use to a few niche applications and with specific SEM models where extensive interlocking strategies are implemented.

Figure 2. a – d) Series of images showing the sequence of operation of the Octane Elite Ultra EDS system on the benchtop during reliability testing. In this example, the system was held at the base temperature for 15 minutes in atmospheric conditions causing significant water condensation on the sensor itself. Note that the electron trap has been removed for visual clarity and several low-level protections overridden to enable this worst-case test to be performed.

At the outset of the Octane Elite Ultra development, a key goal was that the detector should not be damaged by accidental exposure to moisture. By working closely with other AMETEK business units, a proprietary sensor design was developed to mitigate the risk of exposure to moisture using new materials and processes. This development was not without challenges and many iterations of the sensor were tested—and rejected—before product release. Figure 2 shows a series of images captured from the system reliability test that was performed in the final stage of design verification and demonstrates the robustness of the novel sensor design.

A catastrophic failure of the SEM vacuum system and the inbuilt protections systems of the EDS detector were simulated by running the detector at atmospheric conditions (23 °C, 78% relative humidity). The detector was cooled to the minimum temperature achievable under these conditions (-18 °C), Figure 2b, causing water droplets to condense on the cold surface of the EDS sensor. The detector was held at the base temperature before the detector was warmed to room temperature and installed in a vacuum chamber for one day before baseline performance testing was completed. The detector was held at the base temperature for 0.5, 15, 30, 120, and 480 minutes, while the validation was performed after each cooling cycle.

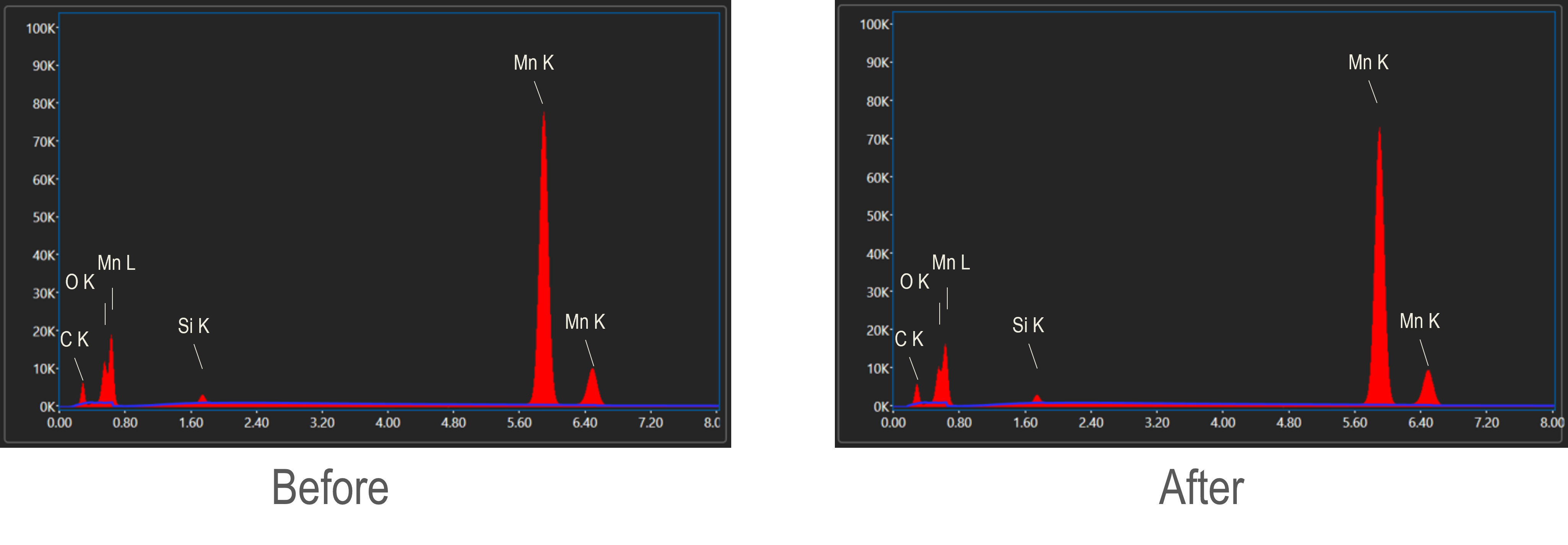

Notably, after re-installing the detector on the SEM chamber and keeping it at vacuum conditions for 24 hours, the Octane Elite Ultra was turned on and cooled to operating temperature without issue. EDS spectra could be collected as normal without any special attention paid to the setup of the device. Evaluation of the effect of the water contamination on performance was done by comparing EDS spectra collected from a Mn standard calibration sample before and after exposure to atmosphere, Figure 3. Remarkably, no change was observed in the total number of counts collected (per second per nA), nor in the resolution of the Mn Ka peak. Moreover, the ratio of the net counts of the low energy peaks (C K and O K from surface contamination) to the Mn Ka peak was also unaffected.

Figure 3. Comparison of the EDS spectra captured with the Octane Elite Ultra windowless EDS system before (left) and after reliability testing (right) with the detector held at base temperature for 15 minutes in this case. The performance of the detector was found to be unaffected by the exposure to atmospheric conditions.

Conclusion

This article documents the astonishing robustness of the Octane Elite Ultra windowless EDS system. By designing an x-ray sensor with outstanding performance combined with the ability to withstand harsh conditions that would lead to catastrophic failure of other detectors, the Octane Elite Ultra EDS system is the first—and only—windowless system that can be installed on a wide variety of SEMs and dual beam instruments in multi-user environments. The Octane Elite Ultra EDS system democratizes the advanced performance of windowless EDS systems.